Pull Over Knitting Sweater

Cixing successfully launched in 2012. As the only listed company in China's flat knitting machine industry, Cixing has a number of advanced patents, among them, a number of technologies reach the international advanced level, product technology and quality level always remain at the forefront of......

Send Inquiry

Product Description

Cixing successfully launched in 2012. As the only listed company in China's flat knitting machine industry, Cixing has a number of advanced patents, among them, a number of technologies reach the international advanced level, product technology and quality level always remain at the forefront of the industry. Cixing has more than 10 subsidiaries, innovative r&d products include computer transversal machines, intelligent transversal machines, transversal machines, fully automatic sewing systems, automatic heating machines, industrial robots, service robots, is a representative company of intelligent equipment of China.

Cixing is the world's largest Jacquard Sweater Flat Knitting Machine manufacturer,which produce best Jacquard Sweater Flat Knitting Machine ,NEW HP series products are the best choice with complete functions, low price, small floor space, and high price performance. Jacquard Sweater Flat Knitting Machine, in addition to jacquard, other patterns of Pull Over Knitting Sweater, such as intarsia , cable, pointel, swelling, structure, and plate can be realized.

Cixing NEW HP Jacquard Sweater Flat Knitting Machine with dynamic stitch function, which can realize multi segment stitch knitting in the same course(one course can support 256 changing areas), without break up the course, increase pattern design diversification to make the Pull Over Knitting Sweater design more novel and fashionable.Can realize different knitting stitch with different knitting area in the same course; The stitch fine adjustment function on both sides can effectively solve the problem of different length of fabric and increase the flatness of fabric.

NEW HP2-52C

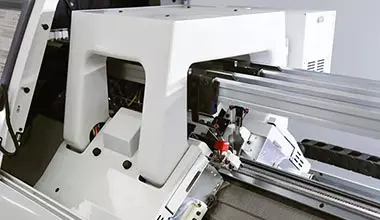

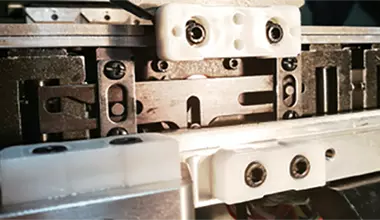

Full motor 5.2-inch ultra-small carriage, motorized transfer cam, rapid return, carriage does not wait when transfer needles, double racking, effectively reducing carriage route and course, greatly improving machine stability and efficiency.

Dynamic stitch function, which can realize multi segment stitch knitting in the same course(one course can support 256 changing areas), without break up the course, increase pattern design diversification, can realize different knitting stitch with different knitting area in the same course; The stitch fine adjustment function on both sides. It can realize the precise control of the single knitting needle on the edge, and the operation is more flexible. Can effectively solve the problem of different length of fabric and increase the flatness of fabric, make the Pull Over Knitting Sweater more artistic.

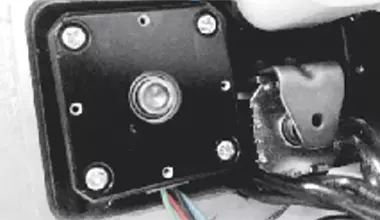

Full Cam Motorized CarriageWith the full cam motorized super small carriage, the cam knit, tuck, transfer actions are controlled by motors, greatly reducing the cam failure rate. The carriage systems are cooperated with optimized course to have shorter return distance, faster return speed, truly achieving high-speed, efficient and stable production. Improve Pull Over Knitting Sweater production efficiency and shorten production time.

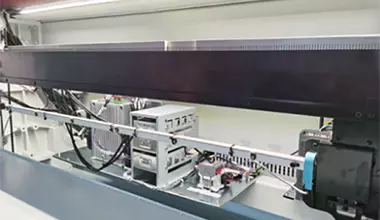

Display ScreenIt adopts industry LCD displayer with graphic touch control, multi color, time monitoring function. The data of knitting amount, time, speed, roller, density, yarn carrier, etc. is clearly shown and can be adiusted in the proless.

Stitch MotorWith dynamic stitch function, using high speed stepping motor, milti stitch function can be achieved in one line.

Servo MotorUsing CANI communication control, can achieve the rapid return and direction changing of the machine carriage, accurate positioning, smooth commutation.

Motorized Inversion BarDriven by motor connecting rod, reversing more accurately.

Yarn StorageYarn Storage could reduce resistance while the yarn is moving, is suitable for fabric with lack of elasticity and brittle fabric such as cashmere yarn, rabbit hair yarn.

Intelligent CombNo waste yarn to knit the fabric bottom, save the machine knitting waste yarn time, reduces the workload of employees. It greatly reduces the enterprise cost. The main yam lead is equipped with a yarn pressing device, so the main yarn lead wire is short, which saves the main yarn and reduces the phenomenon of poor doth dropping and fabric winding caused by the long lead head. Servo closed-loop control is used to accurately control the pulling of the comb, it solve the two different density problems which caused by rib fabric pulling by comb and pulling by roller. The pulling force is more uniform, the fabric effect is better, and the fabric bottom is more beautiful. 5-12G optional.