Aluminum PCB: The Power of Efficient Heat Dissipation in Modern Electronics

2025-05-13

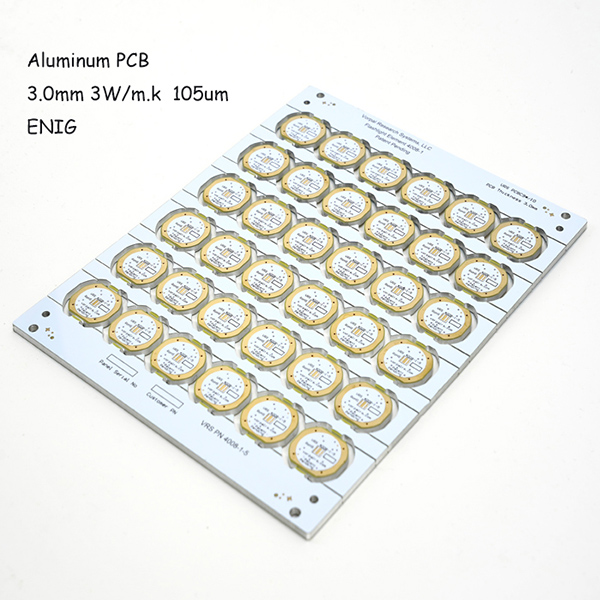

In the ever-evolving world of electronics, the need for high-performance, reliable, and thermally efficient circuit boards has never been greater. As electronic devices become more advanced, the demand for components that can handle higher power outputs while maintaining stability is crucial. One such innovation that meets these demands is Aluminum PCB (Printed Circuit Board). This specialized type of PCB combines the electrical functionality of traditional PCBs with the added benefit of superior heat dissipation, making it an essential part of many modern electronic devices.

What is an Aluminum PCB?

An Aluminum PCB is a type of metal-core PCB that uses aluminum as its base material instead of the traditional fiberglass or composite material. The core material consists of an aluminum plate that provides not only structural support but also an efficient pathway for heat dissipation. Aluminum PCBs are commonly used in applications where heat management is critical, such as in LED lighting, power supplies, automotive electronics, and industrial machinery.

The typical structure of an aluminum PCB includes three layers:

1. Copper Layer: This is where the circuit traces are etched to connect various components on the board.

2. Dielectric Layer: A thin insulating layer that allows for electrical conductivity between the copper and the aluminum base while preventing short circuits.

3. Aluminum Base: The metal base provides structural integrity and exceptional thermal conductivity, ensuring that heat is effectively dissipated from the circuit.

Advantages of Aluminum PCBs

1. Superior Heat Dissipation:

One of the standout features of aluminum PCBs is their superior heat dissipation capabilities. The aluminum base effectively transfers heat away from the components, preventing overheating and ensuring optimal performance. This is especially important in high-power applications, where excessive heat buildup can lead to component failure or reduced lifespan.

2. Enhanced Durability and Strength:

Aluminum is a strong and durable material that provides added mechanical strength to the PCB. This makes aluminum PCBs less prone to damage during handling or in harsh environments. The rigidity of aluminum also helps to maintain the integrity of the circuit, preventing warping or bending.

3. Lightweight and Cost-Effective:

Despite its strength, aluminum is lightweight, which is a key advantage in applications where weight is a critical factor, such as in automotive or aerospace industries. Additionally, aluminum is relatively inexpensive compared to other metals, making aluminum PCBs a cost-effective solution for various applications.

4. Improved Electrical Performance:

Aluminum PCBs offer enhanced electrical performance compared to traditional PCBs. The thermal management capabilities of the aluminum base help prevent thermal expansion or contraction, ensuring that the circuit remains stable and maintains consistent electrical conductivity.

5. Compact Design:

The use of aluminum PCBs allows for more compact designs in electronic products. Since these boards can handle higher power loads with effective heat dissipation, manufacturers can create smaller, more efficient devices without compromising performance or reliability.

Applications of Aluminum PCBs

1. LED Lighting:

The most common application of aluminum PCBs is in LED lighting. LEDs generate significant amounts of heat, and using an aluminum PCB helps dissipate this heat quickly, preventing the LED from overheating and ensuring a longer lifespan. Aluminum PCBs are often used in street lights, commercial lighting, automotive lighting, and consumer electronics like LED TVs and desk lamps.

2. Power Electronics:

Power electronics, such as power supplies, voltage regulators, and inverters, generate a significant amount of heat during operation. Aluminum PCBs are ideal for these applications due to their efficient heat dissipation properties, which keep components at safe operating temperatures and ensure long-term reliability.

3. Automotive Industry:

The automotive industry uses aluminum PCBs for various applications, including lighting systems, sensor modules, and battery management systems. The PCB's ability to withstand high temperatures and mechanical stress makes it suitable for use in the harsh environment of an automobile, where vibrations, temperature fluctuations, and humidity can be significant challenges.

4. Industrial Machinery:

In industrial settings, aluminum PCBs are used in motors, control units, and power management systems. The need for heat management in such equipment is critical, as overheating can lead to breakdowns or inefficiencies. Aluminum PCBs provide the necessary thermal conductivity to ensure that machines operate reliably even under heavy loads.

5. Telecommunications:

Aluminum PCBs are used in various telecommunications devices, such as cell phones, routers, and signal amplifiers, where efficient heat dissipation ensures optimal signal performance and prevents overheating from high-power operation.

Challenges and Considerations

1. Complexity in Manufacturing:

While aluminum PCBs offer many advantages, their manufacturing process can be more complex and require specialized equipment. The aluminum base material requires careful handling to ensure the circuit is properly etched, and the dielectric layer is applied correctly to avoid electrical shorts.

2. Cost:

While aluminum is generally cost-effective, the additional manufacturing steps and the need for specialized equipment can make aluminum PCBs more expensive than traditional PCBs. The cost, however, is usually offset by the long-term reliability and performance benefits of the PCB.

3. Design Limitations:

While aluminum PCBs are highly effective for heat management, they may not be suitable for every type of application. Designers must consider factors like component density, power load, and size constraints before choosing aluminum PCBs over traditional options.

Conclusion

Aluminum PCBs are a game-changer in the world of electronics, offering significant benefits in terms of heat dissipation, durability, and compact design. As industries continue to push for more powerful, energy-efficient, and compact electronic devices, the role of aluminum PCBs becomes even more crucial. Their application across industries such as LED lighting, automotive, telecommunications, and industrial machinery demonstrates the versatility and efficiency of this advanced circuit board technology.

For businesses and engineers seeking to improve the performance and longevity of their electronic products, investing in aluminum PCBs can be a smart choice. By combining superior heat management with cost-effective, lightweight materials, aluminum PCBs are helping pave the way for the next generation of high-performance electronics.