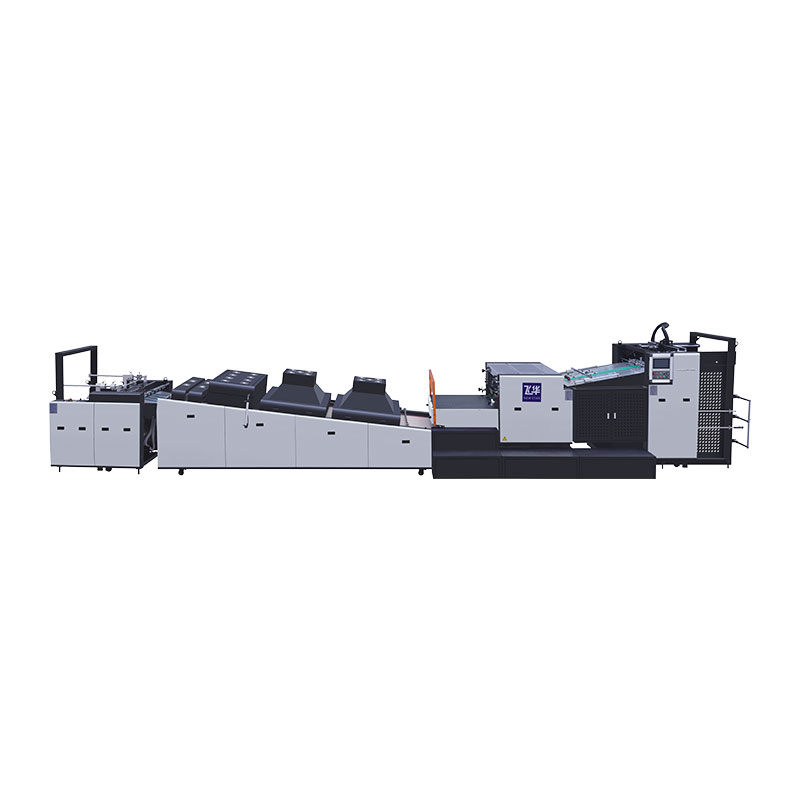

Automatic Coating Machine: Enhancing Efficiency and Precision in Modern Manufacturing

2025-04-07

In today’s fast-paced industrial world, automation is key to improving productivity and maintaining consistent quality. One of the most valuable tools in the production process is the automatic coating machine. This equipment applies a uniform layer of coating material onto the surface of products, ensuring protection, performance, and appearance. From electronics to pharmaceuticals, automatic coating machines have become an essential part of various industries.

What Is an Automatic Coating Machine?

An automatic coating machine is a piece of equipment designed to apply a controlled amount of coating material onto products without the need for manual labor. These machines use a variety of techniques such as spraying, rolling, or dipping to cover surfaces with materials like paint, adhesives, films, or protective chemicals. The coating process is programmed and controlled through automated systems to ensure precision, repeatability, and efficiency.

Benefits of Using Automatic Coating Machines

Automatic coating machines offer several important advantages that make them a valuable investment for manufacturers:

Consistent Quality: Manual coating can result in uneven layers and defects. Automatic machines deliver a uniform coating every time, reducing waste and ensuring product quality.

Higher Productivity: These machines can run continuously with minimal supervision, allowing companies to increase output while saving on labor costs.

Accurate Control: Modern machines offer precise control over coating thickness, speed, and temperature, which is critical for meeting strict industry standards.

Reduced Material Waste: Automation ensures that only the required amount of coating is used, lowering material costs and minimizing environmental impact.

Cleaner Working Environment: Automatic systems reduce the risk of spills and exposure to harmful chemicals, improving safety for operators.

Common Applications

Automatic coating machines are used in a wide range of industries for different purposes:

- Pharmaceuticals: Coating tablets to control release time, mask taste, or protect the active ingredients.

- Electronics: Applying protective coatings to circuit boards to prevent moisture damage.

- Automotive: Coating parts to prevent corrosion and enhance appearance.

- Packaging: Applying heat-seal coatings to improve barrier properties.

- Furniture and Woodworking: Coating wooden surfaces with varnish or lacquer for durability and finish.

Key Features to Look For

When selecting an automatic coating machine, several important features should be considered:

- Control System: A user-friendly interface with programmable settings for flexibility and ease of use.

- Coating Method: The type of application method, such as spray, roll, or dip, should match your production needs.

- Material Compatibility: The machine should be capable of handling the specific coating materials required for your product.

- Cleaning and Maintenance: Easy cleaning and maintenance help extend machine life and reduce downtime.

- Speed and Capacity: Choose a model that matches your production volume for optimal performance.

Conclusion

The automatic coating machine is a powerful tool that helps businesses improve product quality, streamline operations, and reduce costs. Its ability to apply coatings accurately and efficiently makes it a vital part of many modern manufacturing processes. As demand for high-quality and precisely coated products continues to grow, automatic coating technology will play an even greater role in meeting industrial challenges.