Automatic Laminating Machine: A Smart Upgrade for Modern Finishing Needs

2025-04-07

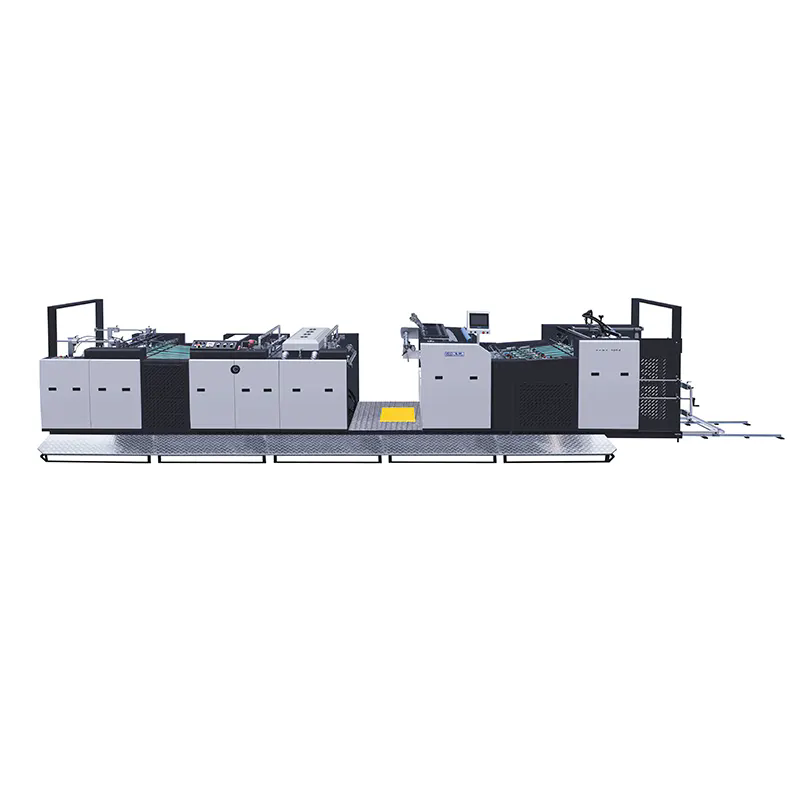

In the competitive world of printing and packaging, quality and efficiency matter more than ever. One machine that plays a crucial role in achieving both is the automatic laminating machine. Designed to apply a protective film over printed materials, this machine enhances durability, improves visual appeal, and boosts the overall value of a product. Whether you’re working with book covers, brochures, packaging boxes, or posters, an automatic laminating machine ensures a sleek and professional finish every time.

What Is an Automatic Laminating Machine?

An automatic laminating machine is a piece of equipment that bonds a layer of plastic film to a printed surface using heat, pressure, and adhesives. Unlike manual laminators, automatic machines handle feeding, lamination, cutting, and stacking with minimal human intervention. The result is faster operation, more consistent quality, and greater efficiency.

These machines come in various sizes and configurations to suit different production needs. Some are built for large-format posters, while others are optimized for smaller items like cards and labels.

Why Use an Automatic Laminating Machine?

Automatic laminating machines provide a range of benefits that help businesses stay ahead of the curve:

Time-Saving Efficiency: Automation reduces manual handling and speeds up the lamination process, making it easier to handle large volumes without delays.

Improved Quality Control: The machine applies uniform pressure and heat, ensuring bubble-free, wrinkle-free finishes with every sheet.

Cost Reduction: Less waste, fewer errors, and minimal labor input translate to long-term savings.

Durability and Protection: Laminated materials are more resistant to moisture, tearing, fading, and everyday wear, making them last longer and look better.

Enhanced Appearance: Lamination gives printed products a glossy or matte finish, enriching colors and providing a premium look and feel.

Applications Across Industries

Automatic laminating machines are widely used across various industries and for many types of printed products:

- Commercial Printing: Business cards, brochures, catalogs, and promotional materials.

- Packaging Industry: Laminating food boxes, cosmetic packaging, and folding cartons.

- Publishing: Book covers and dust jackets for added strength and visual appeal.

- Education and Office Use: Posters, instructional materials, and identification cards.

Key Features to Consider

When selecting an automatic laminating machine, it’s important to consider a few core features:

- Feeding Mechanism: Look for systems that offer accurate sheet feeding to avoid misalignment.

- Temperature and Speed Control: Adjustable settings ensure compatibility with different materials and production speeds.

- Cutting and Separation Options: Some machines include automatic cutting and sheet separation, which further streamline production.

- Lamination Types: Machines may support thermal lamination, cold lamination, or both, depending on the need.

- Ease of Use and Maintenance: A user-friendly interface and accessible components make operation and cleaning much simpler.

Conclusion

An automatic laminating machine is an excellent investment for businesses looking to improve productivity and product quality. By delivering consistent results and reducing the need for manual work, it helps save time, reduce costs, and enhance customer satisfaction. In a market where appearance and durability count, lamination is more than just an extra step — it's a key element of professional finishing.

Whether you’re running a commercial print shop, a packaging company, or an in-house design team, an automatic laminating machine can take your output to the next level with speed, reliability, and polished results.