Exploring the World of Smart Factories: Everything You Need to Know

2025-01-13

What is a Smart Factory?

A smart factory is a highly digitized and connected production facility that uses advanced technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), robotics, and big data to optimize manufacturing processes. It enables factories to autonomously monitor and adjust operations in real-time, leading to increased efficiency, flexibility, and productivity.

What Technologies Are Used in a Smart Factory?

Smart factories rely on a combination of advanced technologies to achieve automation, real-time monitoring, and intelligent decision-making:

1. Internet of Things (IoT): IoT devices and sensors are embedded throughout the factory to collect and exchange data. These sensors can monitor everything from machine performance to inventory levels, providing valuable insights for decision-making.

2. Artificial Intelligence (AI): AI algorithms analyze data to detect patterns, predict equipment failure, and optimize production schedules. It enables smart factories to make decisions autonomously, reducing the need for human intervention.

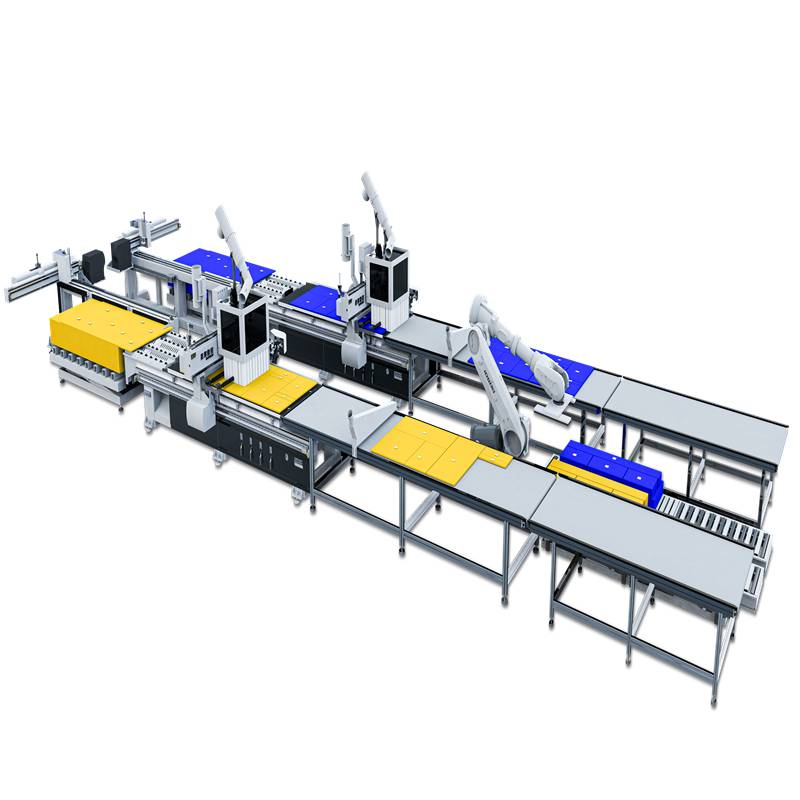

3. Robotics and Automation: Automated robots perform tasks such as assembly, packaging, and material handling. These robots are integrated into the production process and can work collaboratively with human workers.

4. Big Data and Analytics: Data generated from machines, sensors, and production lines are collected and analyzed to optimize processes. Predictive maintenance, production forecasting, and quality control are improved through data-driven insights.

5. Cloud Computing: The cloud allows for seamless data storage and access, enabling real-time monitoring and control of factory operations from anywhere. It facilitates the connection of machines, devices, and systems, regardless of location.

6. Augmented Reality (AR) and Virtual Reality (VR): AR and VR technologies are used for worker training, machine maintenance, and remote support. AR can overlay digital information on physical objects, helping operators make better decisions.

What Are the Benefits of a Smart Factory?

Implementing a smart factory offers numerous advantages for manufacturers across various industries:

1. Increased Efficiency: With real-time data collection and automated processes, smart factories can optimize workflows, reduce waste, and minimize downtime. This leads to higher productivity and reduced operating costs.

2. Improved Quality Control: Smart factories leverage AI and machine learning to monitor production quality in real-time. Automated quality checks and predictive maintenance help prevent defects and ensure high-quality products.

3. Enhanced Flexibility and Customization: Smart factories are highly adaptable, enabling manufacturers to quickly adjust production lines for new products or changes in demand. This flexibility allows for mass customization, where products can be tailored to specific customer requirements.

4. Cost Savings: By streamlining operations and reducing waste, smart factories lower production costs. Predictive maintenance reduces the likelihood of costly equipment breakdowns, and energy-efficient processes help reduce utility expenses.

5. Faster Time-to-Market: With automated processes and real-time monitoring, smart factories can respond more quickly to market demands, accelerating the production cycle and getting products to market faster.

6. Enhanced Worker Safety: With IoT sensors and smart devices, worker safety is significantly improved. Sensors can detect hazardous conditions, alerting workers to potential dangers. Autonomous robots also reduce the risk of human injury in hazardous environments.

How Does a Smart Factory Benefit the Workforce?

While automation plays a significant role in a smart factory, it also offers several benefits to the workforce:

1. Improved Worker Productivity: Automation of repetitive and labor-intensive tasks allows human workers to focus on more complex and creative roles, enhancing job satisfaction and productivity.

2. Training and Skill Development: Smart factories provide opportunities for workers to acquire new skills in advanced technologies such as robotics, AI, and data analytics. This can lead to career advancement and personal growth.

3. Reduced Human Error: Automation and AI-driven processes reduce the likelihood of human error in critical tasks, improving product consistency and overall efficiency.

4. Safer Work Environment: With robots handling dangerous tasks and sensors detecting safety risks, workers are less exposed to hazardous conditions, leading to a safer working environment.

What Challenges Do Companies Face When Implementing a Smart Factory?

While the benefits are significant, there are several challenges associated with transitioning to a smart factory:

1. High Initial Investment: The cost of implementing smart factory technologies, such as sensors, robots, and AI systems, can be prohibitively expensive for some companies. However, the long-term benefits, such as increased efficiency and cost savings, can outweigh the initial costs.

2. Integration with Legacy Systems: Many factories operate with outdated machinery and systems. Integrating these legacy systems with new smart technologies can be complex and costly.

3. Data Security and Privacy: With the massive amount of data being collected and analyzed in a smart factory, there is an increased risk of cyber threats. Ensuring the security of data and factory systems is a priority.

4. Workforce Adaptation: Transitioning to a smart factory requires workers to adapt to new technologies and processes. Companies need to invest in training and reskilling to ensure that their workforce is prepared for the changes.

5. System Complexity: Managing and maintaining the various technologies in a smart factory, such as IoT devices, AI, and robotics, can be complex. This requires skilled personnel and ongoing support to ensure everything runs smoothly.

What Does the Future Hold for Smart Factories?

The future of smart factories is exciting, as technology continues to advance. Here are some trends to watch:

1. AI-Driven Automation: As AI becomes more sophisticated, smart factories will become even more autonomous, making decisions based on real-time data without human intervention.

2. Edge Computing: Instead of relying solely on cloud-based systems, edge computing will allow data processing to occur closer to the source (on the factory floor), reducing latency and enabling faster decision-making.

3. Collaborative Robots (Cobots): The use of cobots, which work alongside human workers, will increase. These robots will handle repetitive tasks, allowing workers to focus on higher-value tasks.

4. Sustainability and Green Manufacturing: As sustainability becomes a growing priority, smart factories will implement green technologies, such as energy-efficient systems, waste reduction processes, and renewable energy sources.

5. 5G Connectivity: The rollout of 5G networks will enable faster and more reliable communication between devices in a smart factory, allowing for even greater levels of automation and real-time monitoring.

Conclusion

Smart factories represent the future of manufacturing, offering businesses the ability to optimize their production processes, reduce costs, and improve product quality. While there are challenges to implementing these technologies, the long-term benefits of increased efficiency, safety, and flexibility make the transition worthwhile. As technology continues to evolve, the smart factory will play an even greater role in shaping the future of global manufacturing.