Functions of Conveyor Transfer Chutes

2024-04-26

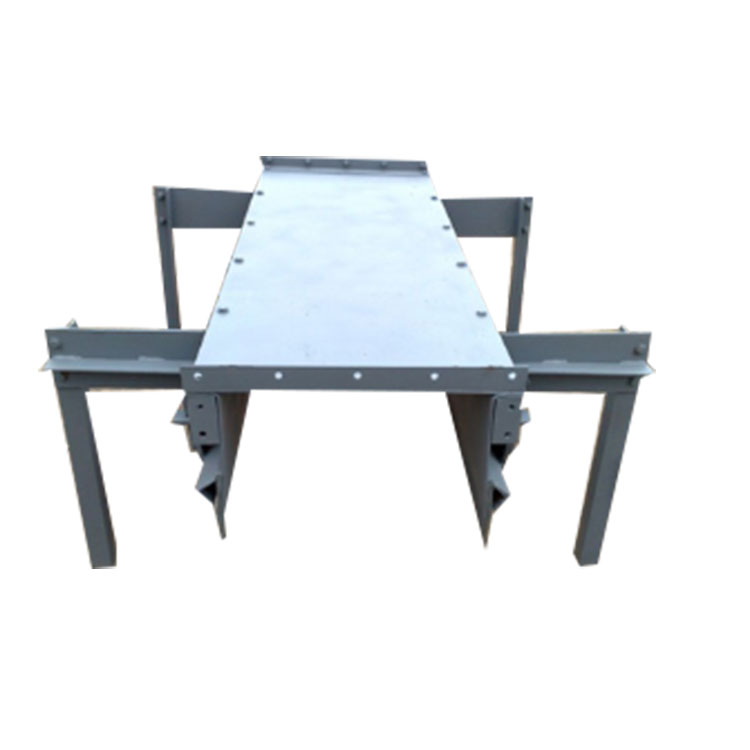

A conveyor transfer chute is a specialized component used in conveyor systems to facilitate the smooth and efficient transfer of bulk materials from one conveyor belt to another, or from a conveyor belt to a storage bin, vessel, or processing equipment. These chutes play a critical role in maintaining the flow of material and preventing spillage, dust emissions, and equipment damage during the transfer process.

Here are some key features and functions of conveyor transfer chutes:

1. Material Flow Control: Transfer chutes are designed to control the flow of bulk materials, ensuring that they are discharged from one conveyor belt onto another conveyor or into a storage container in a controlled and efficient manner. Proper chute design helps minimize material degradation, segregation, and spillage.

2. Smooth Transition: Transfer chutes provide a smooth transition point between conveyor belts or between a conveyor belt and another piece of equipment. This transition is crucial for preventing material impact, degradation, and excessive wear on conveyor components, as well as ensuring the efficient transfer of material without interruption or blockages.

3. Reduction of Dust Emissions: Transfer chutes are often equipped with features such as dust seals, liners, and dust collection systems to minimize dust emissions and improve air quality in the surrounding environment. This is particularly important for handling dusty or fine-grained materials that can create health and safety hazards.

4. Wear Resistance: Transfer chutes are subjected to high levels of wear and abrasion due to the impact and sliding of bulk materials. They are typically lined with abrasion-resistant materials such as rubber, polyurethane, ceramic tiles, or hardened steel liners to prolong the service life of the chute and minimize maintenance requirements.

5. Impact Mitigation: Some transfer chutes incorporate impact-absorbing features such as rock boxes, impact beds, or impact cradles to minimize the impact force of falling material and protect conveyor belts and downstream equipment from damage.

6. Customization: Transfer chutes can be custom-designed to suit the specific requirements of the material being handled, the conveyor system layout, and the operational conditions of the facility. Factors such as material flow rate, particle size, angle of inclination, and drop height are considered during chute design to optimize performance and efficiency.

7. Maintenance and Accessibility: Transfer chutes are designed for ease of maintenance, with features such as access doors, inspection ports, and removable liners to facilitate cleaning, inspection, and repair tasks. Regular maintenance of transfer chutes is essential to ensure continued reliability and efficiency of conveyor systems.

Overall, conveyor transfer chutes are essential components of bulk material handling systems, facilitating the smooth and efficient transfer of materials while minimizing spillage, dust emissions, and equipment wear. Proper chute design and maintenance are crucial for optimizing material flow and conveyor system performance.