Here are some common iron sand casting parts

2023-12-20

Iron sand casting is a widely used process for manufacturing various industrial components. The process involves creating a mold from a pattern made of sand, and then pouring molten iron into the mold cavity. Here are some common iron sand casting parts:

1. Engine Blocks:

- Engine blocks for internal combustion engines are often produced using iron sand casting. The process allows for the creation of complex geometries and internal passages.

2. Cylinder Heads:

- Cylinder heads, which house the combustion chambers and valve train components in an engine, can be cast using iron sand casting.

3. Manifolds:

- Exhaust manifolds and intake manifolds for engines are commonly manufactured using iron sand casting due to its suitability for producing intricate shapes.

4. Valve Bodies:

- Valve bodies for various applications, such as those used in industrial valves or hydraulic systems, can be cast from iron using sand casting.

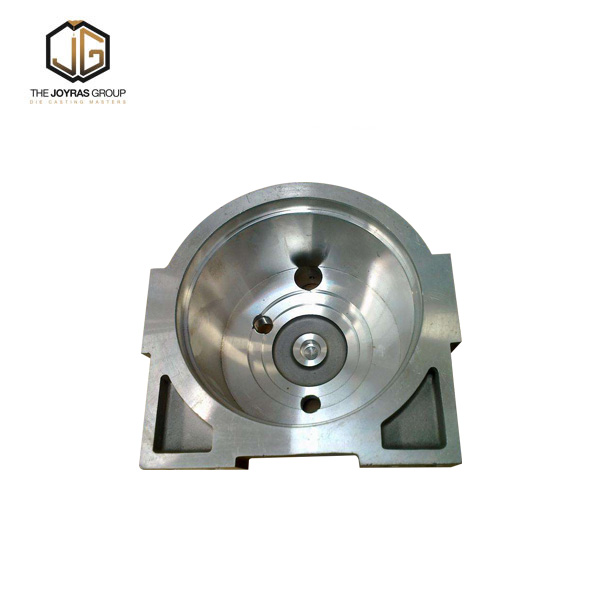

5. Pump Housings:

- Housings for pumps, especially those used in industrial and agricultural applications, can be produced using iron sand casting.

6. Gearboxes:

- Iron sand casting is suitable for creating the housings and other components of gearboxes used in various machinery.

7. Brake Components:

- Brake drums and other components of braking systems can be manufactured using iron sand casting due to the durability and heat resistance of cast iron.

8. Manhole Covers:

- Heavy-duty manhole covers and other municipal infrastructure components are often made using iron sand casting for their strength and durability.

9. Railway Components:

- Various components for railway applications, such as couplings and brake components, can be cast from iron using sand casting.

10. Heavy Machinery Parts:

- Components for construction equipment and other heavy machinery, including housings, brackets, and supports, can be produced using iron sand casting.

11. Pipe Fittings:

- Iron sand casting is commonly used for manufacturing pipe fittings, such as elbows, tees, and flanges, used in plumbing and industrial piping systems.

12. Agricultural Equipment Parts:

- Parts for agricultural machinery, such as plow components, tiller parts, and seeding equipment, can be manufactured using iron sand casting.

13. Hydraulic Components:

- Various hydraulic system components, including pump bodies, valve bodies, and cylinder housings, can be produced using iron sand casting.

Iron sand casting is favored for its ability to produce strong and durable parts with good heat resistance. The specific type of iron used (such as gray iron, ductile iron, or malleable iron) depends on the mechanical properties required for the application. Additionally, post-casting processes like machining and surface finishing may be applied to achieve the desired final product.