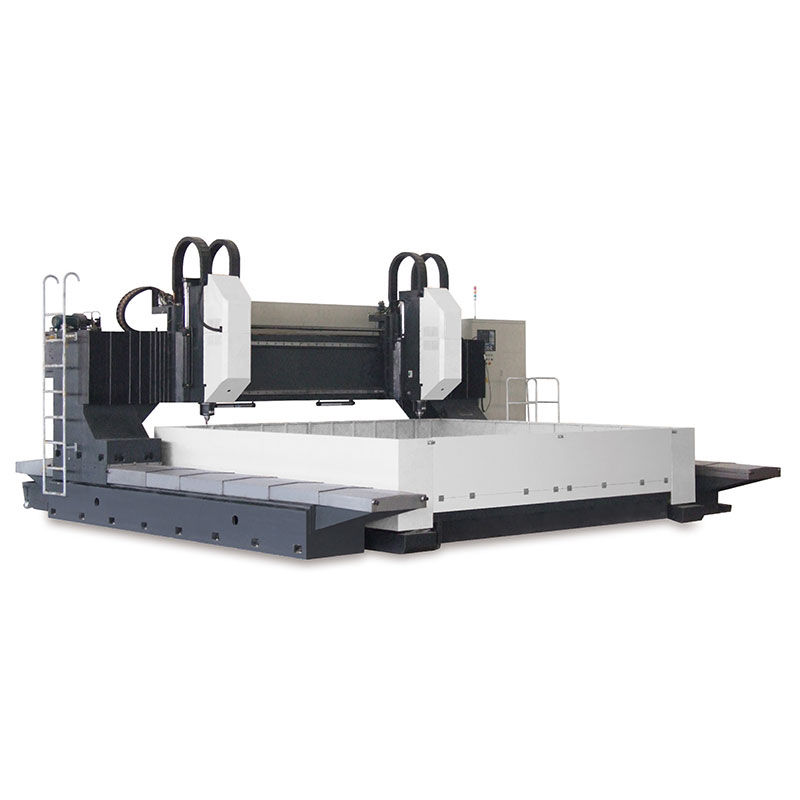

Information about CNC Steel Drilling Machines

2024-07-28

A CNC steel drilling machine is a computer-controlled machine used for precision drilling operations on steel and other metal materials. CNC (Computer Numerical Control) technology enables automation and high accuracy, making these machines essential in manufacturing and metalworking industries. Here’s an overview of CNC steel drilling machines, including their features, applications, and considerations:

Key Features:

1. CNC Control:

- Computer Numerical Control: Utilizes a computer to control the drilling process, allowing for automated and precise drilling operations based on programmed instructions.

2. Drilling Capacity:

- Drill Size and Depth: Capable of handling various drill sizes and depths, depending on the machine’s specifications and tooling.

3. Tooling:

- Interchangeable Tools: Equipped with tool holders that can accommodate different types of drill bits and accessories.

- Automatic Tool Change: Some models feature automatic tool changers for efficient operation.

4. Worktable:

- Adjustable: Includes a worktable that can be adjusted for different workpiece sizes and orientations.

- Clamping System: Often features a clamping system to secure the steel workpieces during drilling.

5. Axis Configuration:

- Multi-Axis Movement: Typically includes multiple axes (X, Y, Z) for precise positioning and drilling. Some advanced models may have additional axes for complex operations.

6. Speed and Feed Rates:

- Adjustable Parameters: Allows adjustment of drilling speed and feed rates to suit different materials and drilling requirements.

7. Safety Features:

- Enclosures and Guards: Equipped with safety enclosures and guards to protect operators from moving parts and debris.

- Emergency Stop: Includes an emergency stop function for immediate shutdown in case of emergency.

Applications:

1. Manufacturing:

- Component Production: Used for drilling holes in steel components and parts for machinery, vehicles, and structural applications.

2. Construction:

- Structural Steel: Drills holes in structural steel beams, columns, and plates used in building construction.

3. Metalworking:

- Custom Fabrication: Ideal for custom metal fabrication projects requiring precise drilling and positioning.

4. Aerospace and Defense:

- Precision Parts: Used to drill high-precision holes in steel components for aerospace and defense applications.

Benefits:

1. Precision and Accuracy:

- High Precision: CNC technology ensures accurate and consistent drilling, reducing errors and improving quality.

2. Automation:

- Efficiency: Automates repetitive drilling tasks, increasing productivity and reducing manual labor.

3. Versatility:

- Adaptability: Capable of handling various sizes and types of steel workpieces, making it suitable for a wide range of applications.

4. Complex Operations:

- Complex Drilling: Can perform complex drilling patterns and operations that would be difficult to achieve manually.

Considerations:

1. Machine Size and Capacity:

- Workpiece Size: Ensure the machine has the capacity to handle the size and weight of the steel workpieces you intend to drill.

2. Tooling and Accessories:

- Compatibility: Choose tooling and accessories compatible with the machine’s specifications and the type of drilling required.

3. Programming:

- Software: Familiarize yourself with the CNC programming software and ensure it meets your needs for creating and modifying drilling programs.

4. Maintenance:

- Regular Maintenance: Perform regular maintenance to ensure optimal performance and longevity of the machine. This includes checking alignment, lubrication, and tool condition.

5. Training:

- Operator Training: Ensure operators are properly trained in using the CNC machine, including programming, setup, and safety procedures.

Installation and Operation:

1. Setup:

- Installation: Ensure proper installation and leveling of the CNC machine according to the manufacturer’s guidelines.

- Calibration: Calibrate the machine to ensure accurate positioning and drilling.

2. Programming:

- Create Programs: Use CNC programming software to create drilling programs based on the specific requirements of the workpieces.

- Upload Programs: Load the programs into the machine’s control system.

3. Operation:

- Load Workpieces: Securely load and clamp the steel workpieces onto the worktable.

- Run Programs: Execute the drilling programs and monitor the machine for proper operation.

4. Maintenance:

- Routine Checks: Perform routine checks and maintenance to keep the machine in good working condition.

CNC steel drilling machines are essential tools in modern manufacturing and metalworking, offering precision, efficiency, and versatility. By understanding the features and considerations associated with these machines, you can make informed decisions and ensure successful operations in your projects.