Key Points about Steel Belt Tumble Type Shot Blasting

2024-07-10

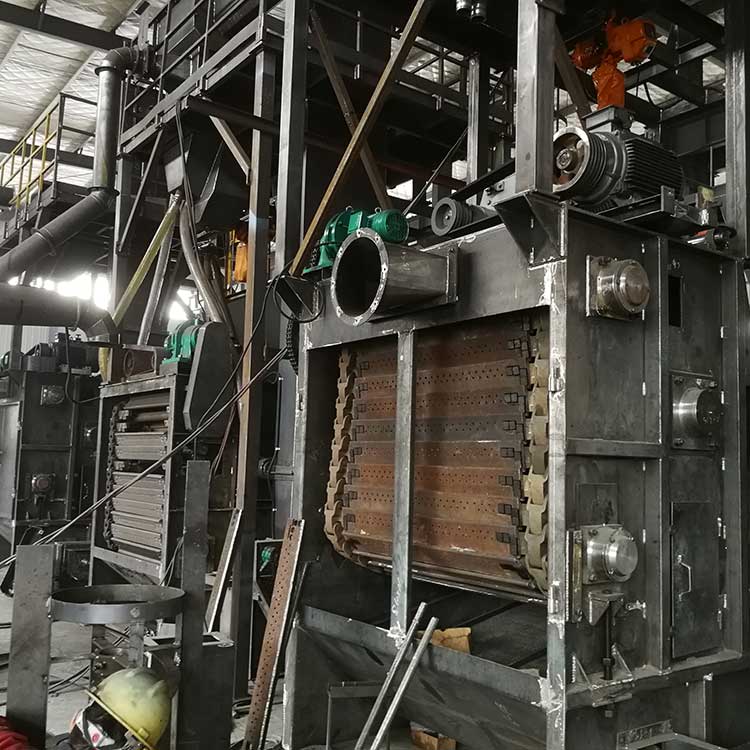

Steel belt tumble type shot blasting refers to a specific type of shot blasting machine used primarily for cleaning, descaling, and surface preparation of metal parts. Here are key points about steel belt tumble type shot blasting:

Operation and Design

1. Tumble Action:

- Continuous Tumbling: Metal parts are placed on a steel belt conveyor within a rotating drum or chamber.

- Rotation: The drum rotates, causing the parts to tumble and expose all surfaces to the shot blasting process.

2. Shot Blasting Media:

- Steel Shots or Grits: Small metallic particles (shots) or abrasive grits are propelled at high velocity onto the surface of the metal parts.

- Abrasive Action: Removes rust, scale, old coatings, and contaminants from the metal surface through impact and abrasion.

3. Steel Belt Conveyor:

- Continuous Operation: Parts move through the shot blasting process continuously on the steel belt conveyor.

- Durable Construction: The steel belt is designed to withstand the impact of the blasting media and the wear and tear of continuous operation.

Applications

1. Surface Cleaning and Preparation:

- Metal Parts: Used for cleaning and preparing various metal components such as castings, forgings, weldments, and stamped parts.

- Removal of Contaminants: Removes rust, scale, oxides, and other surface contaminants to prepare parts for further processing (e.g., coating, painting).

2. Deburring and Desanding:

- Burr Removal: Eliminates sharp edges and burrs from machined parts.

- Sand Removal: Cleans and descales foundry sand from castings.

3. Surface Finishing:

- Enhanced Surface Finish: Achieves a uniform surface texture and appearance on metal parts.

- Surface Roughening: Prepares surfaces for subsequent treatments such as coating adhesion or surface bonding.

Benefits

1. Efficiency and Consistency:

- High Production Rates: Processes large volumes of parts efficiently due to continuous operation.

- Uniform Treatment: Ensures consistent surface preparation and finish across all treated parts.

2. Cost-Effectiveness:

- Reduced Labor: Automates the cleaning and preparation process, reducing labor costs and improving productivity.

- Longevity: Durable steel belt conveyor reduces maintenance and replacement costs compared to other conveyor types.

3. Environmental Considerations:

- Dust Control: Enclosed design with dust collection systems minimizes airborne contaminants.

- Media Recycling: Enables recycling and reuse of shot blasting media, reducing waste and environmental impact.

Maintenance and Safety

1. Regular Inspection:

- Check Belt Condition: Inspect the steel belt and components for wear, damage, or misalignment.

- Safety Checks: Ensure safety guards, interlocks, and ventilation systems are functioning correctly.

2. Operator Training:

- Proper Use: Train operators on safe handling practices, including loading and unloading parts and monitoring the shot blasting process.

- Protective Gear: Provide personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection.

Steel belt tumble type shot blasting machines are essential in industries such as automotive, aerospace, foundries, and manufacturing where consistent and efficient surface preparation of metal parts is required. Their design and operation contribute significantly to improving product quality, reducing production costs, and enhancing workplace safety.