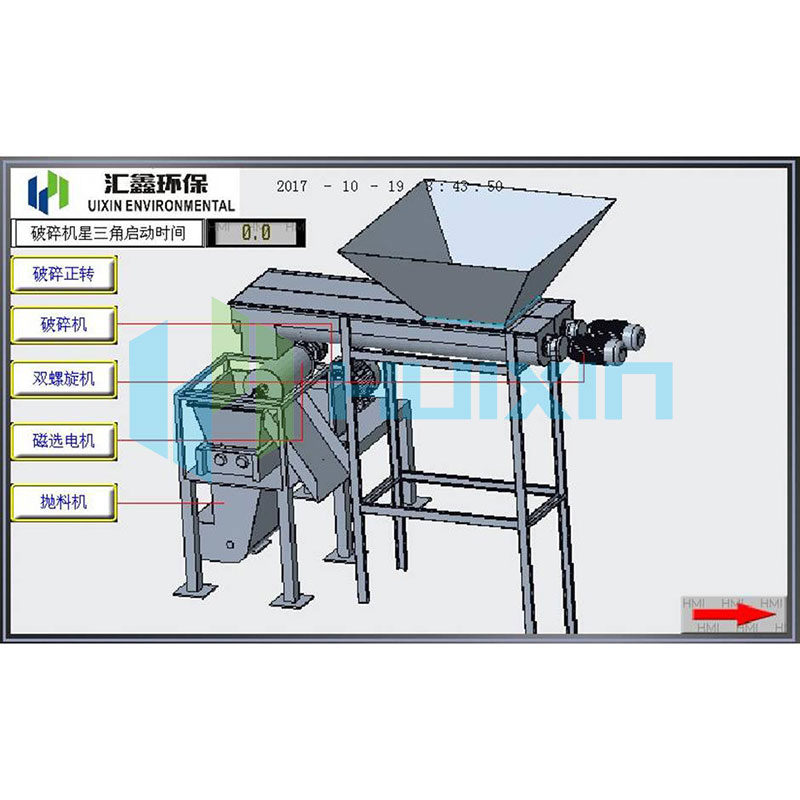

Operation of Shearing Crushers

2024-06-21

A shearing crusher, also known as a shear shredder, is a type of industrial crusher used for size reduction or material shredding. It utilizes shearing forces to reduce the size of materials, often used in recycling operations or waste management. Here’s an overview of shearing crushers, their operation, applications, and considerations:

Operation of Shearing Crushers:

1. Shearing Mechanism:

- Cutting Blades: Typically equipped with multiple sharp blades or knives arranged on a rotor or within a cutting chamber.

- Shearing Action: Material is fed into the crusher, where the rotating blades cut and shear the material into smaller pieces.

- High-speed Rotation: The rotor or cutting mechanism operates at high speeds to efficiently shred or reduce the size of the material.

2. Size Reduction:

- Shearing crushers are effective for reducing a wide range of materials, including plastics, rubber, wood, paper, textiles, and metal scrap.

- They can handle both bulky items and materials in various forms (e.g., solid, sheet, film) due to their versatile cutting capabilities.

3. Controlled Output Size:

- Depending on the design and settings, shearing crushers can produce consistent particle sizes suitable for further processing or recycling.

- Output size can be adjusted by changing the screen or grate size within the crusher.

Applications of Shearing Crushers:

1. Recycling Industry:

- Used extensively in recycling facilities to process scrap materials, including plastic containers, metal cans, tires, and electronic waste (e-waste).

- Prepares materials for recycling by reducing them to smaller, manageable sizes.

2. Waste Management:

- Helps reduce the volume of bulky waste materials, such as furniture, mattresses, and appliances, for easier handling and disposal.

- Facilitates waste-to-energy processes by shredding biomass materials like wood or agricultural waste.

3. Manufacturing and Production:

- Utilized in manufacturing processes to shred materials for reuse or recycling within the production cycle.

- Prepares materials for subsequent processing stages, such as melting, molding, or extrusion in plastics manufacturing.

4. Environmental Cleanup:

- Used in environmental remediation efforts to process contaminated materials or debris, reducing the environmental impact of hazardous substances.

Considerations When Using Shearing Crushers:

1. Material Compatibility:

- Ensure the crusher is suitable for the specific type and size of material being processed to avoid damage or inefficiency.

2. Maintenance and Safety:

- Regular maintenance of blades and cutting elements is essential to ensure optimal performance and longevity of the crusher.

- Safety protocols should be followed to prevent accidents, including proper guarding and operator training.

3. Throughput Capacity:

- Consider the throughput capacity of the crusher, which determines the rate at which materials can be processed.

- Choose a crusher with sufficient capacity to meet production demands without causing bottlenecks.

4. Energy Efficiency:

- Opt for crushers with energy-efficient designs to minimize operational costs and environmental impact.

- Select models with advanced control systems or automation features for optimized performance.

Shearing crushers play a vital role in various industries by efficiently reducing material size and preparing materials for recycling or disposal. Their robust construction and cutting-edge technology make them indispensable for modern waste management and recycling operations.