Puller for Flatbed Coverstitch: Enhancing Precision and Efficiency in Sewing

2024-08-26

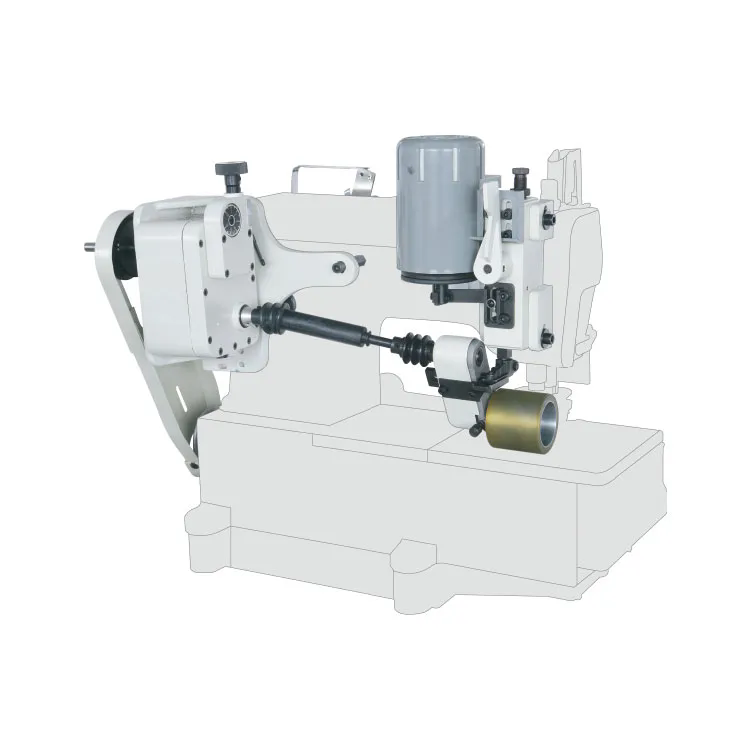

In the world of sewing and garment manufacturing, achieving high-quality, precise stitching is crucial for creating professional and durable garments. One tool that significantly contributes to this goal is the puller for flatbed coverstitch. This essential accessory enhances the performance of coverstitch machines, providing numerous benefits for both small-scale and large-scale sewing operations. In this blog, we'll explore what a puller for flatbed coverstitch is, its features, benefits, and how it can transform your sewing process.

What is a Puller for Flatbed Coverstitch?

A puller for flatbed coverstitch is an accessory designed to aid in the feeding and alignment of fabric as it passes through a coverstitch machine. The puller works by gripping and feeding the fabric evenly, ensuring consistent stitching and preventing issues like puckering or stretching. It is especially useful for sewing long, straight seams on flatbed coverstitch machines, which are commonly used in the apparel industry for hemming and finishing garments.

Key Features of a Puller for Flatbed Coverstitch

1. Fabric Feeding Mechanism: The puller grips the fabric and pulls it through the machine at a controlled speed, ensuring even tension and alignment. This helps to maintain consistent stitch quality throughout the length of the seam.

2. Adjustable Settings: Many pullers come with adjustable settings that allow users to fine-tune the feed rate and pressure according to the type of fabric and stitching requirements. This flexibility ensures optimal performance for different sewing tasks.

3. Durable Construction: Pullers are typically made from robust materials designed to withstand the wear and tear of regular use. This durability ensures long-term reliability and consistent performance.

4. Ease of Installation: Most pullers are designed to be easily attached to flatbed coverstitch machines. They often feature quick-mount systems that facilitate straightforward installation and removal.

5. Compatibility: Pullers are designed to work seamlessly with a variety of flatbed coverstitch machines, making them a versatile addition to any sewing setup.

6. Smooth Operation: The puller's design ensures smooth, uninterrupted fabric feeding, reducing the likelihood of fabric snags or jams during stitching.

Benefits of Using a Puller for Flatbed Coverstitch

1. Improved Stitch Quality: By providing consistent fabric feeding, a puller ensures even tension and alignment, resulting in high-quality, professional-looking stitches without puckering or stretching.

2. Enhanced Efficiency: The puller's ability to handle long seams and multiple layers of fabric streamlines the sewing process, increasing productivity and reducing the time required for stitching.

3. Reduced Operator Fatigue: With the puller handling the fabric feeding, operators experience less strain and fatigue, allowing them to work more comfortably and efficiently over extended periods.

4. Versatility: The puller can be used with various types of fabrics and stitching projects, making it a valuable tool for handling different sewing tasks and applications.

5. Minimized Fabric Damage: By ensuring gentle, controlled feeding of the fabric, the puller reduces the risk of damage such as stretching or distortion, preserving the integrity of the material.

6. Consistency in Production: For garment manufacturers, the puller helps maintain consistent stitch quality and appearance across multiple garments, contributing to a uniform and professional end product.

How to Use a Puller for Flatbed Coverstitch

1. Install the Puller: Follow the manufacturer's instructions to attach the puller to your flatbed coverstitch machine. Ensure it is securely mounted and properly aligned with the sewing mechanism.

2. Adjust Settings: Set the puller’s feed rate and pressure according to the type of fabric you are working with and the requirements of your stitching project. Refer to the machine and puller manuals for guidance on optimal settings.

3. Prepare the Fabric: Position the fabric under the machine’s presser foot, ensuring it is aligned correctly. The puller will take over the feeding process once the stitching begins.

4. Start Sewing: Begin stitching as usual. The puller will grip and feed the fabric through the machine, maintaining consistent tension and alignment throughout the seam.

5. Monitor Operation: Keep an eye on the fabric feeding and stitching process to ensure smooth operation. Make any necessary adjustments to the puller settings if needed.

6. Maintain the Puller: Regularly clean and inspect the puller for any signs of wear or damage. Follow the manufacturer’s maintenance recommendations to ensure long-term performance.

Common Applications

1. Garment Manufacturing: Ideal for sewing hems and seams in garments, particularly those made from stretchy or delicate fabrics.

2. Sportswear Production: Used for stitching athletic wear and performance apparel, where precise and durable stitching is essential.

3. Home Sewing Projects: Beneficial for hobbyists and home sewers working on large or intricate sewing projects that require consistent stitching quality.

4. Textile Industry: Suitable for use in industrial settings where high-volume sewing and consistent stitch quality are critical.

5. Fashion Design: Helps designers achieve precise and professional finishes on custom garments and fashion pieces.

Choosing the Right Puller for Flatbed Coverstitch

1. Compatibility: Ensure the puller is compatible with your specific flatbed coverstitch machine model. Check the manufacturer’s recommendations or consult with a sewing equipment specialist.

2. Adjustability: Look for a puller with adjustable settings that can be customized to suit different fabrics and sewing requirements.

3. Durability: Choose a puller made from high-quality materials that can withstand regular use and provide reliable performance.

4. Ease of Use: Opt for a puller with straightforward installation and operation, ensuring that it integrates seamlessly with your existing sewing setup.

5. Customer Reviews: Read reviews and seek recommendations from other users to gauge the performance and reliability of the puller you are considering.

Conclusion

The puller for flatbed coverstitch is a valuable tool that enhances the precision, efficiency, and quality of sewing operations. By providing consistent fabric feeding and reducing operator fatigue, it contributes to achieving professional results and streamlining the sewing process. Whether you're working in garment manufacturing, sportswear production, or home sewing projects, investing in a high-quality puller can transform your sewing experience and elevate the standard of your finished products. Embrace the benefits of this essential accessory and enjoy smoother, more efficient sewing with every stitch.