Some notable copper alloy tubes and their applications

2024-01-04

Copper alloy tubes refer to tubes made from copper and other alloying elements. Copper alloys are created by combining copper with other metals to enhance specific properties such as strength, corrosion resistance, electrical conductivity, and heat resistance. The addition of alloying elements allows manufacturers to tailor the characteristics of copper tubes for various applications. Common copper alloys used for tubes include brass, bronze, and cupronickel.

Here are some notable copper alloy tubes and their applications:

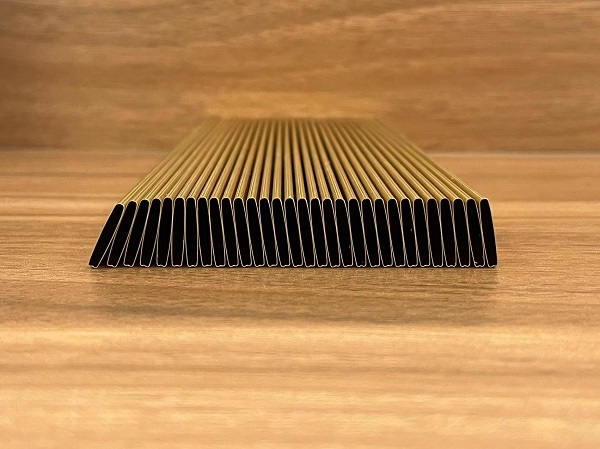

1. Brass Tubes:

- Brass is an alloy of copper and zinc. Brass tubes are known for their excellent corrosion resistance, machinability, and thermal conductivity. They find applications in heat exchangers, plumbing systems, industrial equipment, and decorative applications due to their attractive golden color.

2. Bronze Tubes:

- Bronze is an alloy of copper and tin, with other elements such as aluminum, phosphorus, or silicon often added. Bronze tubes offer high strength, wear resistance, and corrosion resistance. They are used in marine applications, bearings, bushings, and various industrial components.

3. Cupronickel Tubes:

- Cupronickel alloys, such as those containing copper and nickel, are known for their excellent corrosion resistance in seawater and resistance to biofouling. Common cupronickel tubes include 90/10 (90% copper, 10% nickel) and 70/30 (70% copper, 30% nickel) compositions. They are widely used in marine applications, heat exchangers, and condensers.

4. Admiralty Brass Tubes:

- Admiralty brass is an alloy of copper with small amounts of zinc and tin. It offers good corrosion resistance in both freshwater and seawater environments. Admiralty brass tubes are commonly used in condensers, heat exchangers, and other marine applications.

5. Aluminum Brass Tubes:

- Aluminum brass is a copper alloy with aluminum as the main alloying element. This alloy provides good corrosion resistance and heat transfer properties. Aluminum brass tubes are used in applications such as power plants, desalination plants, and shipbuilding.

6. Phosphor Bronze Tubes:

- Phosphor bronze is a copper alloy with tin and phosphorus as alloying elements. Phosphor bronze tubes exhibit high strength, wear resistance, and excellent corrosion resistance. They are commonly used in bushings, bearings, and electrical connectors.

7. Silicon Bronze Tubes:

- Silicon bronze is a copper alloy with silicon as the primary alloying element. This alloy offers good strength, corrosion resistance, and weldability. Silicon bronze tubes find applications in plumbing, architectural elements, and artistic works.

8. Copper-Nickel Tubes:

- Copper-nickel alloys, such as 90/10 and 70/30, are widely used in tubing for their excellent corrosion resistance, especially in marine environments. They are used in condensers, heat exchangers, and seawater piping systems.

Copper alloy tubes are chosen based on the specific requirements of an application, considering factors such as corrosion resistance, mechanical strength, conductivity, and cost. The versatility of copper alloys makes them suitable for a wide range of industries, including aerospace, automotive, marine, HVAC (heating, ventilation, and air conditioning), and industrial manufacturing.