Streamlining Production: The Importance of a Copper Tape Packaging Line

2024-08-15

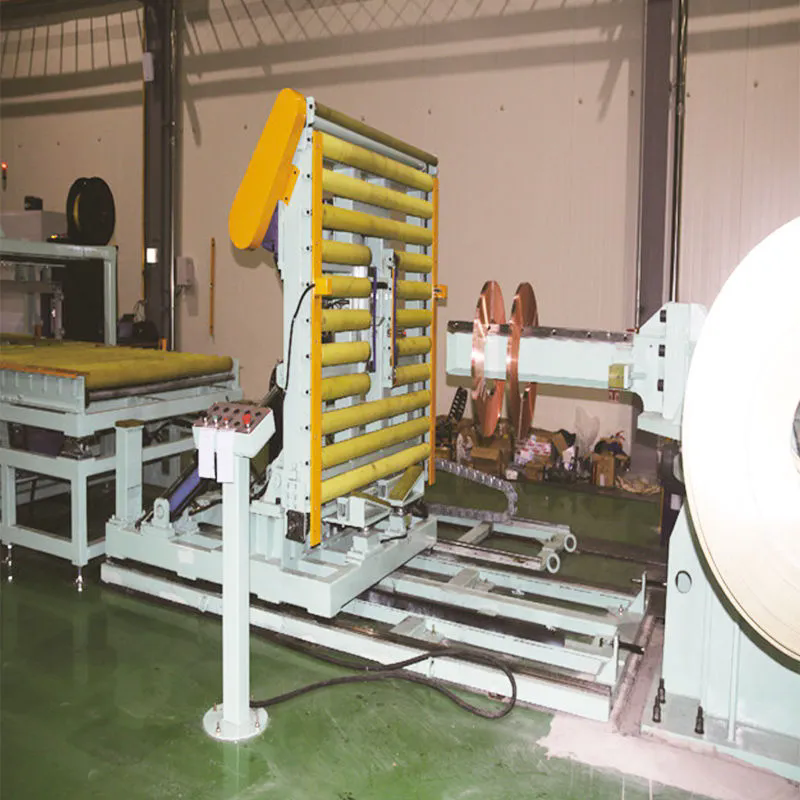

In the ever-evolving world of manufacturing and packaging, efficiency and precision are paramount. For industries that rely on copper tape—such as electronics, automotive, and construction—the packaging process is as crucial as the product itself. A copper tape packaging line is designed to streamline this process, ensuring that copper tape is packaged efficiently, accurately, and with minimal waste. Let’s delve into the significance of a copper tape packaging line, its components, benefits, and considerations for setting up an effective system.

1. What is a Copper Tape Packaging Line?

A copper tape packaging line is a specialized assembly of machinery and equipment designed to package copper tape rolls or spools. Copper tape, used extensively in electrical and electronic applications, needs to be packaged carefully to prevent damage and ensure easy handling. The packaging line automates various stages of the packaging process, from unwinding and cutting the tape to labeling and sealing the packages.

2. Components of a Copper Tape Packaging Line

A well-designed copper tape packaging line typically includes several key components:

- Unwinding Unit: This component feeds the copper tape into the packaging line from large rolls. It ensures a smooth and consistent unwinding process to prevent tangling or breakage.

- Cutting Mechanism: The cutting mechanism is responsible for cutting the copper tape into desired lengths or rolls. Precision cutting is essential to meet specific packaging requirements and ensure uniformity.

- Rewinding Unit: After cutting, the copper tape is often rewound onto smaller spools or rolls. The rewinding unit ensures that the tape is neatly wound and ready for further processing.

- Labeling System: The labeling system applies labels to the packaged copper tape, providing essential information such as product specifications, barcodes, and manufacturing details. Accurate labeling is crucial for inventory management and traceability.

- Packaging and Sealing Unit: This component packages the copper tape into protective materials, such as plastic bags or boxes, and seals them to ensure they remain intact during transportation and storage.

- Quality Control Station: A quality control station inspects the finished packages for any defects or inconsistencies. This ensures that only high-quality products are shipped to customers.

- Conveyor System: The conveyor system transports the copper tape and finished packages through the various stages of the packaging line, ensuring smooth and efficient movement between components.

3. Benefits of a Copper Tape Packaging Line

Implementing a copper tape packaging line offers several advantages:

- Increased Efficiency: Automation streamlines the packaging process, reducing manual labor and increasing overall efficiency. This leads to faster production rates and higher output.

- Consistent Quality: Automated systems ensure uniform cutting, winding, and packaging of copper tape, leading to consistent product quality. This reduces the likelihood of defects and improves customer satisfaction.

- Reduced Waste: Precise cutting and efficient packaging reduce material waste and product loss. This contributes to cost savings and environmental sustainability.

- Improved Safety: Automation reduces the need for manual handling of copper tape, minimizing the risk of injuries and accidents. It also ensures that packaging processes are performed in a controlled and safe manner.

- Enhanced Tracking and Traceability: The integration of labeling and tracking systems allows for better inventory management and traceability. This helps in maintaining accurate records and managing product distribution.

- Customization: Packaging lines can be customized to accommodate different sizes, lengths, and types of copper tape. This flexibility allows manufacturers to meet diverse customer requirements.

4. Considerations for Setting Up a Copper Tape Packaging Line

When setting up a copper tape packaging line, several factors should be considered to ensure optimal performance:

- Production Requirements: Assess the production volume and packaging requirements to determine the appropriate size and configuration of the packaging line. Consider factors such as tape width, length, and packaging format.

- Space and Layout: Plan the layout of the packaging line to ensure efficient workflow and space utilization. Proper placement of equipment and conveyors can improve operational efficiency.

- Integration with Existing Systems: Ensure that the packaging line can be integrated with existing manufacturing and inventory systems. Compatibility with other equipment and software is crucial for seamless operations.

- Maintenance and Support: Choose equipment that is easy to maintain and comes with reliable support services. Regular maintenance is essential for preventing downtime and ensuring the longevity of the equipment.

- Cost and ROI: Evaluate the cost of implementing a packaging line against the expected return on investment. Consider factors such as increased efficiency, reduced labor costs, and improved product quality.

5. Future Trends in Copper Tape Packaging

As technology advances, several trends are shaping the future of copper tape packaging:

- Smart Packaging: The integration of IoT and smart technologies allows for real-time monitoring and data collection. Smart packaging systems can provide insights into production performance and product quality.

- Sustainability: There is a growing emphasis on sustainable packaging materials and practices. Manufacturers are exploring eco-friendly options and reducing the environmental impact of packaging processes.

- Advanced Automation: Innovations in automation technology continue to enhance packaging efficiency and precision. New developments in robotics and machine learning are expected to drive further improvements in packaging lines.

Conclusion

A copper tape packaging line is a vital component of modern manufacturing, providing efficiency, consistency, and quality in the packaging process. By automating key stages of packaging, manufacturers can improve productivity, reduce waste, and enhance product quality. When setting up a packaging line, careful consideration of production requirements, space, and equipment can ensure a successful and cost-effective solution. As technology continues to evolve, the future of copper tape packaging holds exciting possibilities for even greater efficiency and sustainability.