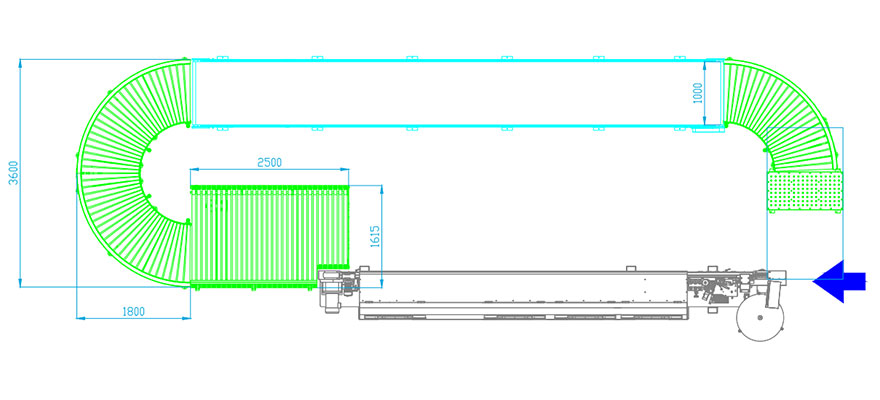

Returning Conveyor Line for Edge banding machine

1.Product IntroductionReturning Conveyor Line for Edge banding machine can effectively reduce production cost and improve production efficiency. Returning Conveyor Line for Edge banding machine is suitable for the smooth transmission and conveying process which is with low beating rate and good perf......

Send Inquiry

Product Description

1.Product Introduction

Returning Conveyor Line for Edge banding machine can effectively reduce production cost and improve production efficiency. Returning Conveyor Line for Edge banding machine is suitable for the smooth transmission and conveying process which is with low beating rate and good performance. Returning Conveyor Line for Edge banding machine is mainly used for edge banding machine U-returning of furniture panel, the roller center distance is 80mm which can pass workpiece with small size like 250*80mm.

2. Product Parameter (Specification)

ModelFQ-WDHZ

Main Beam240*50 Aluminum

Roller Dia.56mm with rubber covered

Rubber thickness3mm

Distance between rollers80mm

Min panel size200*200mm

Max panel size1200*2400mm

Panel thickness10-60mm

Conveying speed10-28 meters/min

Frequency converterTaiwan Delta

Power supply (voltage and frequency)3 phase, 380V, 50Hz, 4.3KW

Edge banding machine length6000mm

Edge banding machine working height900±50mm

3. Product Feature And Application

1.The supporting feet are bent integrally, and the supporting lug seat is formed by high-quality integrated die casting

2.The roller surface is covered with imported bright silver gray rubber (wear-resistant and not vulnerable)

3.The edge sealing of the workpiece on the rotary line is not off-line, which effectively saves 50% of the labor intensity

4.The whole line equipment has good stability, high manual operation safety and simple equipment maintenance

4.Product Details